Table of Contents

Introduction

If you’ve ever worn a comfortable t-shirt, a cozy sweater, or stretchy yoga pants, you’ve experienced the work of knitted fabric manufacturers. These companies create fabrics that feel soft, stretch easily, and fit our bodies perfectly. Whether you’re starting a clothing brand, looking for suppliers, or simply curious about how fabrics are made, this guide will explain everything you need to know about knitted fabric manufacturers in simple, easy-to-understand language.

What Are Knitted Fabrics?

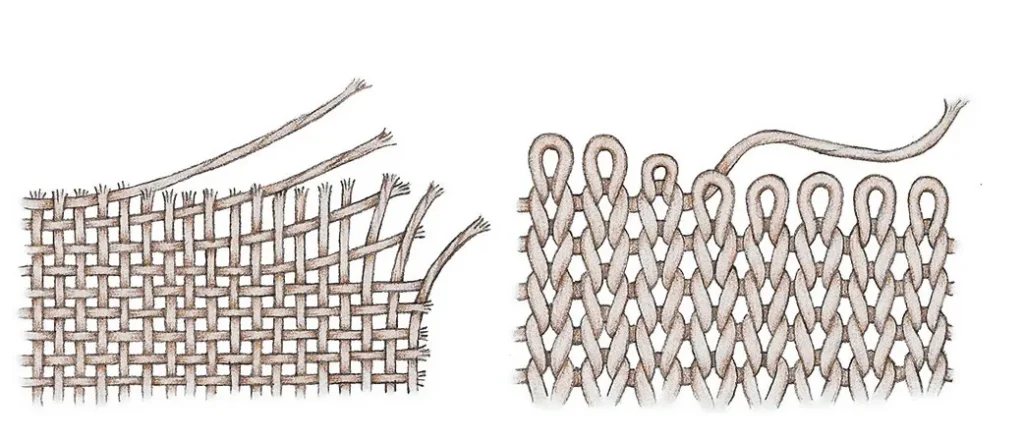

Before we talk about the manufacturers, let’s understand what knitted fabrics actually are. Unlike woven fabrics that are made by crossing threads over and under each other like a checkerboard, knitted fabrics are created using loops of yarn connected together. Imagine knitting with needles—that’s essentially what machines do, but much faster and on a larger scale. When you hand-knit a scarf, you’re creating the same basic loops that industrial machines create, just one stitch at a time instead of thousands per second.

Knitted fabrics are popular because they’re stretchy, comfortable, and flexible. They don’t wrinkle as easily as some woven fabrics, and they move with your body. This is why t-shirts, socks, underwear, and athletic wear are usually made from knitted fabric. The stretch in knitted fabric comes from the looped structure, which allows the fabric to expand and contract without tearing. This property makes knitted fabrics ideal for clothing that needs to move and breathe with the wearer.

Understanding Different Types of Knitted Fabrics

There are several types of knitted fabrics, and understanding them will help you know what different knitted fabric manufacturers specialize in. Each type has its own characteristics, advantages, and common uses in the fashion industry.

Single Jersey is the simplest type of knitted fabric that you’ll encounter. It’s thin, lightweight, and smooth on one side while having a bumpy texture on the back. You’ll find it in basic t-shirts and casual clothing. It’s affordable and easy to produce, which is why many manufacturers offer it as their most popular option. Single jersey is perfect for warm weather clothing because it’s breathable and doesn’t trap too much heat. However, it can curl at the edges and wrinkle more easily than other types of knitted fabrics.

Double Jersey is thicker and stronger than single jersey, making it a premium option for manufacturers who want to offer quality products. It looks similar on both sides and doesn’t curl at the edges like single jersey does. Many premium t-shirts and underwear use double jersey because it lasts longer and feels more luxurious against the skin. The double structure means it takes longer to produce and uses more yarn, which is why it costs more than single jersey. However, customers appreciate the durability and comfort that comes with this type of fabric.

Fleece is warm and cozy, making it perfect for cold weather clothing. It’s made by brushing the fabric to create soft, fluffy fibers that trap warm air. This is what you find in winter sweatshirts, hoodies, and blankets. Fleece is popular because it provides excellent insulation while remaining lightweight and easy to care for. Many manufacturers have invested in fleece production because there’s consistent demand for warm clothing, especially in colder climates.

Rib Knit is stretchy and fitted, which is why you see it in cuffs on sleeves, waistbands, and collars. It hugs the body nicely and provides a neat, finished look to clothing. The ribbed structure creates vertical lines that you can see and feel. Rib knit is particularly popular in athletic wear and fitted clothing because it provides compression and support while allowing freedom of movement. Many knitted fabric manufacturers keep rib knit production as a standard offering because it’s used in almost every type of garment.

Interlock Knit is smooth and balanced, looking similar on both sides. It’s thicker than single jersey and very durable. Many children’s clothes and quality basics are made from interlock knit because it’s soft, safe, and long-lasting. Interlock knit is produced on specialized machines that create a more complex stitch structure, which is why it’s more expensive to produce than single jersey. The extra durability and comfort make it worth the investment for quality-conscious manufacturers.

How Knitted Fabric Manufacturers Work

Understanding the manufacturing process helps you appreciate the work that goes into every piece of fabric you use. The journey from raw materials to finished fabric involves multiple stages, each one crucial to creating quality products. Let’s break down the process into simple steps that show how knitted fabric manufacturers transform basic materials into the comfortable fabrics we wear every day.

Step 1: Getting Raw Materials

Everything starts with yarn. Knitted fabric manufacturers source yarn made from different materials like cotton, polyester, wool, or blends of these. Cotton is popular for comfort and breathability, making it ideal for summer clothing and underwear. Polyester is durable and affordable, which is why it’s used in everything from athletic wear to home furnishings. Wool provides warmth and is perfect for winter clothing and accessories. Many manufacturers now blend these materials to get the best of each—comfort from cotton, durability from polyester, and warmth from wool all in one product.

The choice of raw materials is one of the most important decisions that knitted fabric manufacturers make because it directly affects the final product. They must balance quality with cost, considering what their customers need and what they can afford. Some manufacturers specialize in premium natural materials like organic cotton, while others focus on affordable synthetic blends for fast fashion brands.

Step 2: Preparing the Yarn

Before knitting, the yarn must be prepared carefully. It’s wound onto cones or bobbins and checked for quality. Manufacturers test the yarn’s strength and consistency to ensure it will perform well in the machines. Any weak spots or irregularities are identified and fixed. This preparation step is crucial because poor-quality yarn leads to poor-quality fabric. Skipping this step or rushing through it is a common mistake that results in products that break easily or look uneven.

During preparation, technicians check for the correct yarn count, which determines how thick or thin the final fabric will be. They ensure the yarn is wound evenly without tangles or loose spots. They also verify that the yarn color is consistent if they’re working with pre-dyed yarn. This attention to detail in the preparation stage prevents problems later in the manufacturing process.

Step 3: The Actual Knitting

This is where the magic happens. Modern knitting machines are computer-controlled and incredibly fast. They have thousands of tiny needles that loop the yarn together in precise patterns. The machines can produce different patterns and designs automatically based on computer programming. A single machine can knit yards of fabric every hour, working at speeds that would be impossible for any human to match.

Skilled technicians monitor the machines to ensure everything is working perfectly. They watch for broken needles, tension problems, or yarn breaks that could damage the fabric. These operators are highly trained because their attention directly impacts the quality of the final product. The knitting machines can create different patterns and designs based on their programming, which is how manufacturers can make plain fabrics or fancy patterned ones. Some machines are so advanced that they can produce complex designs that would take a person weeks to hand-knit.

Step 4: Finishing and Treatment

Once the fabric is knitted, it’s not quite ready for customers. It needs finishing touches that improve its appearance, feel, and performance. The dyeing process adds color to the fabric using special dyes that are mixed carefully to match exact color specifications. The fabric is then washed to remove any oils or impurities that accumulated during knitting. Softening chemicals are applied to make the fabric feel nicer and more comfortable. Heat setting uses high temperatures to help the fabric hold its shape and maintain its properties after washing.

These finishing processes ensure the fabric feels good, looks vibrant, and maintains its quality through many wash cycles. Different manufacturers use different finishing techniques, and these choices affect the final product. Some manufacturers use traditional methods that take longer but produce premium results, while others use faster methods to keep costs down. The choice of finishing techniques is a key differentiator between basic fabric manufacturers and premium ones.

Step 5: Quality Control

Good knitted fabric manufacturers check their work carefully at every stage. They inspect the fabric for holes, loose threads, color inconsistencies, and sizing issues. They test how much the fabric shrinks when washed to ensure customers won’t have problems with garments fitting poorly after washing. They check the strength and elasticity to make sure the fabric will last through normal use and washing. Any fabric that doesn’t meet standards is removed before it leaves the factory.

Quality control is not just a final step but something that happens throughout the manufacturing process. Machines have sensors that can detect problems automatically and stop production when issues occur. Technicians pull samples regularly to test in laboratories. This comprehensive approach to quality is what separates professional manufacturers from cheaper alternatives. When you buy from knitted fabric manufacturers with strong quality control, you get consistent products that your customers will love.

Finding the Right Knitted Fabric Manufacturers

If you need to source knitted fabrics, how do you find the right manufacturer? This can seem overwhelming, but breaking it down into steps makes the process manageable. The key is to be patient and thorough because choosing the wrong manufacturer can lead to problems, delays, and poor-quality products that damage your business reputation.

Research Different Manufacturers

Start by researching knitted fabric manufacturers in different regions. Asia, especially China, India, Vietnam, and Bangladesh, is the largest manufacturing hub because of lower labor costs and established infrastructure. Europe, particularly Germany and Italy, is known for high-quality fabrics and innovation. You can find manufacturers through online directories and B2B websites where companies list their products and services.

Trade shows and textile exhibitions are excellent places to see products in person and meet manufacturers face-to-face. Referrals from other businesses in your industry can be invaluable because they come with real experience. Industry groups and associations often maintain lists of vetted manufacturers. Simple Google searches and LinkedIn can also help you discover manufacturers you might not find through official channels.

When researching, read reviews and case studies from other customers. Look at how long companies have been in business because longevity usually indicates reliability. Check their social media and website for signs of professionalism and quality. Pay attention to how they communicate—good manufacturers are responsive and professional in all their interactions.

Check Their Qualifications

Look for manufacturers that have certifications because these prove they follow standards and procedures. ISO certifications show they follow international quality standards and have proper systems in place. OEKO-TEX certification means the fabrics are safe and free from harmful chemicals that could irritate skin. GOTS (Global Organic Textile Standard) certification means they use organic materials and ethical labor practices. These certifications aren’t just official stamps—they represent actual testing by third parties who verify that standards are being met.

Beyond certifications, research the manufacturer’s experience with your specific type of fabric. Some manufacturers specialize in fleece, others in jersey, and others in technical fabrics. Working with a manufacturer who specializes in what you need usually gives better results than working with a generalist. Ask about their experience with customers like you. Have they worked with other clothing brands? Have they handled custom orders before?

Ask the Right Questions

When you contact potential manufacturers, ask comprehensive questions that will help you evaluate if they’re a good fit. Ask about their experience and how long they’ve been in business because experience usually correlates with reliability. Find out the types of fabrics they specialize in to ensure they can produce what you need. Ask about their minimum order quantities because this affects whether you can work with them. Understand their production timeline and whether they can meet your deadlines.

Learn about their quality control processes to ensure they maintain standards. Discuss their pricing and payment terms to understand the full cost. Ask whether they can customize fabrics to your needs because many manufacturers offer this service.

Don’t be shy about asking detailed questions. Good manufacturers expect questions and appreciate customers who are thorough. Manufacturers who seem annoyed by questions or unwilling to provide information are probably not good partners. The manufacturers who take time to answer your questions carefully are the ones worth working with.

Request Samples

Always ask for samples before placing a large order. Good knitted fabric manufacturers will send you small samples of their fabrics without charging too much or at all. Examine them carefully because you need to verify that the quality meets your expectations. Feel the texture to understand how soft and smooth it is. Check the color in different lighting because colors can look different in natural light versus artificial light.

Wash them to see if they shrink, fade, or develop problems. Test their stretch and durability to ensure the fabric will perform well in finished garments. Samples are your opportunity to verify quality before committing to a large purchase.

When comparing samples from different manufacturers, look at them side by side. Note the subtle differences in softness, weight, drape, and color. Sometimes the differences between good and excellent fabric are subtle but make a big difference in the final product. Take your time with this evaluation because it’s crucial to your decision.

Compare Prices

Get quotes from multiple manufacturers and compare them carefully. Don’t just compare the price per pound or yard because that’s only part of the story. Look at the quality, minimum orders, and shipping costs too. Sometimes a slightly higher price is worth it if the quality is better and the manufacturer is more reliable. Request itemized quotes that break down costs so you understand what you’re paying for. Ask about volume discounts because buying more usually means paying less per unit. Find out about payment terms and whether they require payment upfront or if they offer payment after delivery.

Price is important, but it shouldn’t be your only consideration. Buying from the cheapest manufacturer often leads to quality problems that cost you more in the long run through customer complaints, returns, and damage to your brand reputation. Find the balance between price and quality that works for your business model.

Working with Knitted Fabric Manufacturers

Clear Communication

Write down everything in clear, simple language before you order. Specify exactly what you need, including the type of knitted fabric you want, the color and any patterns, the weight and thickness requirements, the quantity you need, your desired delivery date, your budget, and any special requirements. Miscommunication is one of the biggest problems between buyers and manufacturers, and it causes delays and quality issues. Being clear and specific prevents these problems from happening in the first place.

Use multiple methods of communication to ensure your message is understood. Email provides a written record. Phone calls or video meetings help clarify confusing points. Share detailed specifications in writing and confirm that the manufacturer understands them. If there are language barriers, consider using translation services or hiring a consultant who speaks both languages.

Discuss Minimums and Pricing

Most manufacturers have minimum order quantities (MOQ) because they can’t economically produce very small orders. This might be 500 pounds, 1000 yards, or even a full shipping container. Understand their minimums and negotiate if possible. Explain your situation honestly—if you’re a startup, many manufacturers will work with you. Ask about volume discounts because buying more usually means paying less per unit. A quantity discount structure encourages you to order more while helping the manufacturer reduce costs through longer production runs.

Be realistic about what you can order. If the minimum is 1000 yards and you can only use 500, either negotiate the minimum or work with other designers to combine orders. Some suppliers allow splitting orders between multiple buyers if they all meet the same specifications.

Build Trust Gradually

Start with a smaller order to test the relationship rather than committing to a large purchase immediately. If the manufacturer delivers quality products on time, increase your orders. Good manufacturers value long-term relationships because it means stable business for them. Once they know you’re reliable and serious, they’re more likely to offer better prices and accommodate your requests. As you build trust, you become a valued customer rather than just a transaction.

Share your success with your manufacturer. Tell them when customers love the fabric or when your business grows because of the quality they provided. Manufacturers appreciate knowing that their work contributes to their customers’ success. This positive relationship often leads to preferential treatment, priority scheduling, and willingness to help solve problems.

Plan for Lead Times

Manufacturing takes time that you need to plan for. Knitting takes several days or weeks depending on the quantity. Dyeing and finishing add more time. Quality control and packaging take additional days. Shipping can take weeks or even months if you’re ordering from overseas. Plan ahead and give realistic timelines. Don’t expect immediate delivery unless you’re paying premium prices for rush orders. Building extra time into your schedule prevents stressful situations where you’re pressing the manufacturer for faster delivery.

Create a timeline that works backward from when you need the fabric. If you need fabric in three months, order at least four months in advance to account for unexpected delays. Keep in regular contact with the manufacturer to track progress and identify potential problems early.

The Importance of Quality and Certifications

Quality matters because it affects your customers’ satisfaction and your business reputation. Reputable knitted fabric manufacturers follow strict quality standards throughout their operations. They test fabrics for durability to ensure the fabric handles regular washing and wearing without falling apart or developing holes. They test for color fastness to verify the color won’t fade or bleed onto other clothes during washing.

They measure shrinkage to ensure the fabric doesn’t shrink more than acceptable limits when washed. They check elasticity to confirm it will stretch appropriately and return to its original shape. They verify safety by ensuring there are no harmful chemicals or substances in the fabric.

Certifications from reputable organizations prove that these tests are performed by qualified laboratories using standardized methods. When you buy from certified manufacturers, you’re getting independent verification that standards are being met. This matters to your customers because many people care about the safety and quality of the products they wear.

Sustainability and Ethical Manufacturing

More people care about where their clothes come from and how they’re made. Good knitted fabric manufacturers are adopting sustainable practices that reduce environmental impact while treating workers fairly. Some use organic cotton that’s grown without harmful pesticides, which is better for the environment and often softer for customers’ skin. Others reduce water waste in dyeing processes because dyeing traditionally uses enormous amounts of water. Many are switching to eco-friendly dyes that don’t harm aquatic ecosystems.

Manufacturers recycle fabric scraps and waste materials instead of sending them to landfills. The best ones treat workers fairly with good wages and safe working conditions.

If sustainability matters to you or your customers, ask manufacturers about their environmental practices and certifications. Some manufacturers are becoming leaders in sustainable fashion, which is good for the planet and often good for business too because consumers are increasingly willing to pay more for ethically made products.

Common Challenges and How to Handle Them

Working with manufacturers can sometimes be challenging, and understanding common issues helps you navigate them successfully. Quality problems can occur when fabric arrives with defects like holes, loose threads, or color variations. The solution is to communicate immediately with clear photos documenting the problems. Agree upfront on what happens if quality standards aren’t met. Most good manufacturers will replace faulty batches without argument because they take pride in their work.

Delays happen in manufacturing for various reasons including machine breakdowns, material shortages, or unexpected weather. Build extra time into your schedule to account for these possibilities. Maintain regular communication to track progress and address problems early. If delays occur, work with the manufacturer to find solutions rather than getting angry, because cooperation usually gets faster resolution than conflict.

Communication issues arise from language differences and time zone challenges that create misunderstandings. Use written communication and send clear specifications. Follow up regularly to ensure understanding. If language is a significant barrier, consider hiring a consultant who can communicate with the manufacturer in their language.

Cost surprises happen when hidden fees appear in invoices. Get detailed quotes that break down all costs including materials, labor, dyeing, finishing, and shipping. Request written confirmation of all costs before ordering to prevent surprises.

The Future of Knitted Fabric Manufacturing

The industry is evolving rapidly in exciting directions. New technologies are making manufacturing faster and more efficient while improving quality. Sustainability is becoming standard practice rather than optional because companies and customers demand it. Smart fabrics that monitor health or regulate temperature are being developed for medical and athletic applications. Automation using robots and artificial intelligence is increasing production speed and consistency. Digital printing is allowing manufacturers to create custom patterns without traditional screen printing.

For buyers, this means better fabrics, more options, and hopefully more ethical production in the future. For manufacturers, it means investing in new technology and training workers for more skilled jobs. The industry is becoming more sophisticated and customer-focused, which benefits everyone involved.

Conclusion

Finding reliable knitted fabric manufacturers doesn’t have to be complicated. Texoraglobal specializes in connecting businesses with trusted manufacturers who deliver quality fabrics on time and within budget. With our expertise in sourcing knitted fabrics and deep relationships with manufacturers worldwide, we help you navigate the entire process from research to delivery.

Our team handles quality verification, price negotiation, and communication so you can focus on growing your business. Contact Texoraglobal today for free consultation and discover how we make sourcing knitted fabrics simple, reliable, and profitable for your brand.